Soil Moisture Probes test Concrete

April 16, 2021

Van Walt has partnered IMKO for decades. IMKO, based near Karlsruhe in Germany was owned by the Koehler family. Kurt Koehler was always rather more interested in extracting every last milli-percentage of accuracy from their patented Trime TDR technology than any commercial considerations. As such IMKO became known for the excellence of their soil moisture probes which were and are still the benchmark for soil moisture research.

In the last few years IMKO was purchased by Endress+Hauser, still a family business but with 14,000 employees. Whereas IMKO’s Trime TDR probes still thrive it is with great interest that we see an additional focus of their technology in a sector rather unknown to us: Materials Testing. Below I reproduce their latest newsletter which makes for fascinating reading.

Vincent van Walt, April 2021

Special Edition! Strong Products – Strong Trust!

Dear business partners,

the term innovation is derived from the Latin “innovare”: “to renew”. But just renewing or developing is useless if it serves no other / higher purpose. This way innovation means more: It is about converting ideas into successful products. One of our success stories is that our SONO-W/Z won the innovation award at BAUMA in 2016. With that the product became noticed in the industry. But we always had more in mind with this instrument and improved our “baby” continuously over the last years. Succesfully attracting a great community of customers, selling more instruments and helping our customers to get their job done right converts ideas into innovations: more reliable, with more precision in more countries.

Have fun reading today’s special edition.

The entire IMKO team wishes you a Happy Easter.

Kind regards

Timo Camek

Handheld probe SONO-W/Z | 2.0

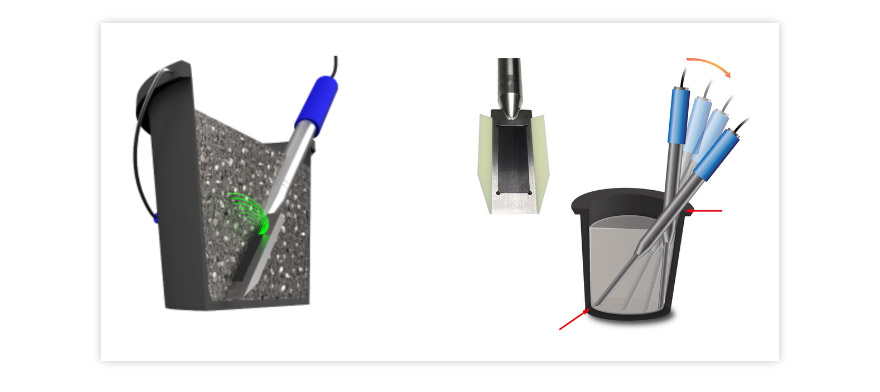

We have refined our SONO-W/Z handheld probe for the quick on-site determination of the water-cement value of fresh concrete.

We significantly improved the accuracy by using a new design of the semiconductor chip in 2019. The new semiconductor chip leads to a significantly better coupling and decoupling of the high-frequency measurement signal.

In a further step, we have improvemed the factory calibration. The so-called “basic balancing” is carried out individually for each probe as an IMKO standard procedure. Even tiny and unavoidable variance of the precision electronics interacting with the mechanical measuring head are now compensated. The current method employs two measuring points against reference materials.

The factory commissioning software uses these values to determine a best-fit straight line and stores this in the basic settings of the probe. This guarantees perfect functioning in the common measuring and application range of all tool values. The device user is now able to set the device for the current measurement task by adapting task-specific measurement parameters.

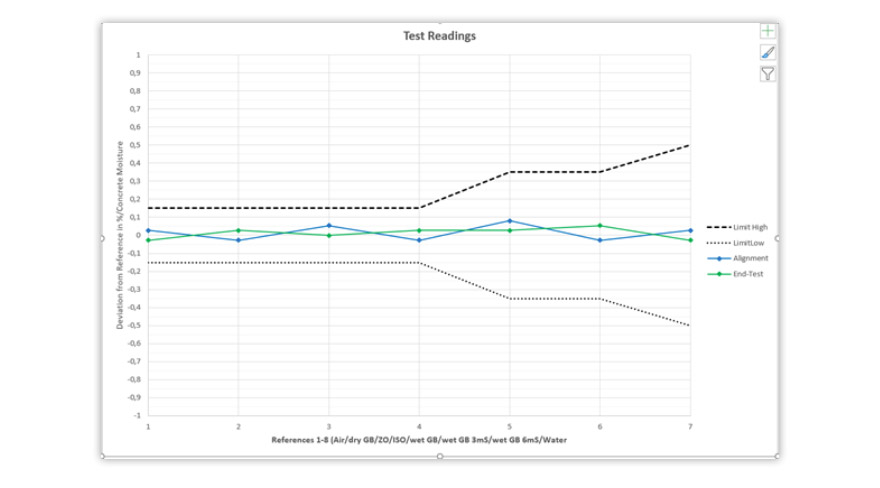

Good is not good enough for us. Following the claim to continuously improve our measuring devices, we have now focused on the “basic balancing”. This is possible because our TRIME measuring principle allows a measurements over the full range of permittivity (air = 1 to water = 81) – which is one of the unique selling points of our technology. Here is, what changed: Instead of using two measuring points as reference before, storing a regression line – in future seven (7) reference points will be used over the entire range of the dielictric constant and the regression line will be replaced by a polynomial curve of the 5th degree.

As a result, this means that even the smallest non-linearities / deviations among individual sensors are now compensated. This enables the synchronization among devices and ensures that individual instruments are able to describe material conditions in a fleet use-case. The advantages are obvious:

– further increase of accuracy to +/-2..3 l/m³ in the typical measuring range (after recipe-specific adjustment)

– device rapid check for correct functioning by measurements in the media of air and water

– device synchronization in the fleet to increase process reliability

According to feedback from the global marketplace, todays‘ version of the SONO-W/Z is already matching most users‘ expectations, but the latest upate and new functionalities of the SONO-W/Z 2.0 exceeds the expectations of repeatabilities and accuracies in fresh concrete. The Optionally available calibration certificate opens even new potentials.

For example, you can validate the SONO-W/Z as your own measuring device as part of an audit. In addition, there are new possibilities with regard to the process chain, as it is now possible to reference 2 or more devices against each other, e.g. to compare the concrete directly after production in the factory and during acceptance test on the construction site. That pays into the account of future BIM-systems (Building Information Management) and traceablities in the construction business.

You might also be interested in...

Spot measurement v. continuous environmental monitoring

August 25, 2023Environmental monitoring has developed considerably over the years. From the time when a consultant went out monthly or quarterly with a dip tape to monitor the groundwater level in a borehole, wind forward...

Read MoreMeasuring Nitrates (NO3, NO3-N) in the field

June 20, 2023The interest in Nitrates is nothing new. One way or another we have been measuring them for half a century.

Read MoreSave time, save money, save effort, get better results – use low-flow sampling…

June 1, 2023A client recently contacted me to ask if we can repair their high flow purge pump and or sell then a new one. They were using it for (among other applications) to purge a 70m deep bore 3 times for a...

Read MoreVan Walt Environmental Equipment

A small selection of our environmental equipment